Advantages And Disadvantages Of Fluidized Bed

Drying is a key unit process in the chemical food and pharmaceutical industries.

Advantages and disadvantages of fluidized bed. 1 This process has high thermal efficiency. Below are the main Fluid bed dryer advantages and disadvantages in the pharmaceutical bulk drug food and chemical industries. The available fluidized bed dryers offer a wide range of benefits depending on their unique design.

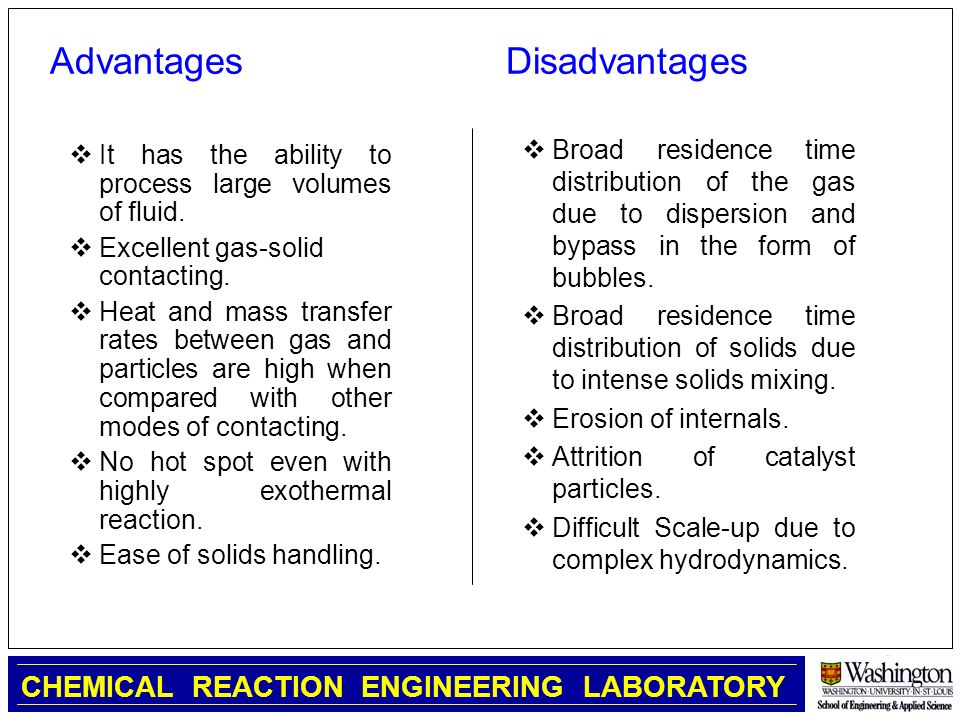

Difficulty involved in processing needle or platelet-shaped particles. Some advantages of using a fluidized bed include uniform particle mixing and temperature gradients. Due to the advantages of fluidized bed reactors a large amount of research is devoted to this technology.

Advantages of Fluidized Bed Dryer. A fluidized bed may be defined as the bed of solid particles Fluidized Combustion The fluidized bed of a boiler contains mainly particles of an inert Air flow velocity in boiler furnace vs. Heterogeneous has phase reactions with a catalyst.

In case power is. Better temperature control. There are a few disadvantages to using fluidized beds.

High thermal efficiency is usually achieved if part of the thermal energy for drying is supplied by the internal heat exchanger. Many people think that this filter hinders the surface agitation because they cant remove carbon dioxide content so they cant add oxygen in the water good bacteria will wipe out some of the oxygen. Cons Disadvantages of Fluidized Moving Bed Filter.

One disadvantage is the removal of unreacted coal particles together with the ash which leads to lower carbon conversion efficiency than other gasifiers. Nowadays in the aquarium hobby there are many forms of filtration available from the suppliers so sometimes it can get confusing as to which are the right ones to use on your aquarium. You can also visit our Fluid bed dryer product Page here where you can request a quote and also read about fluid bed processors.