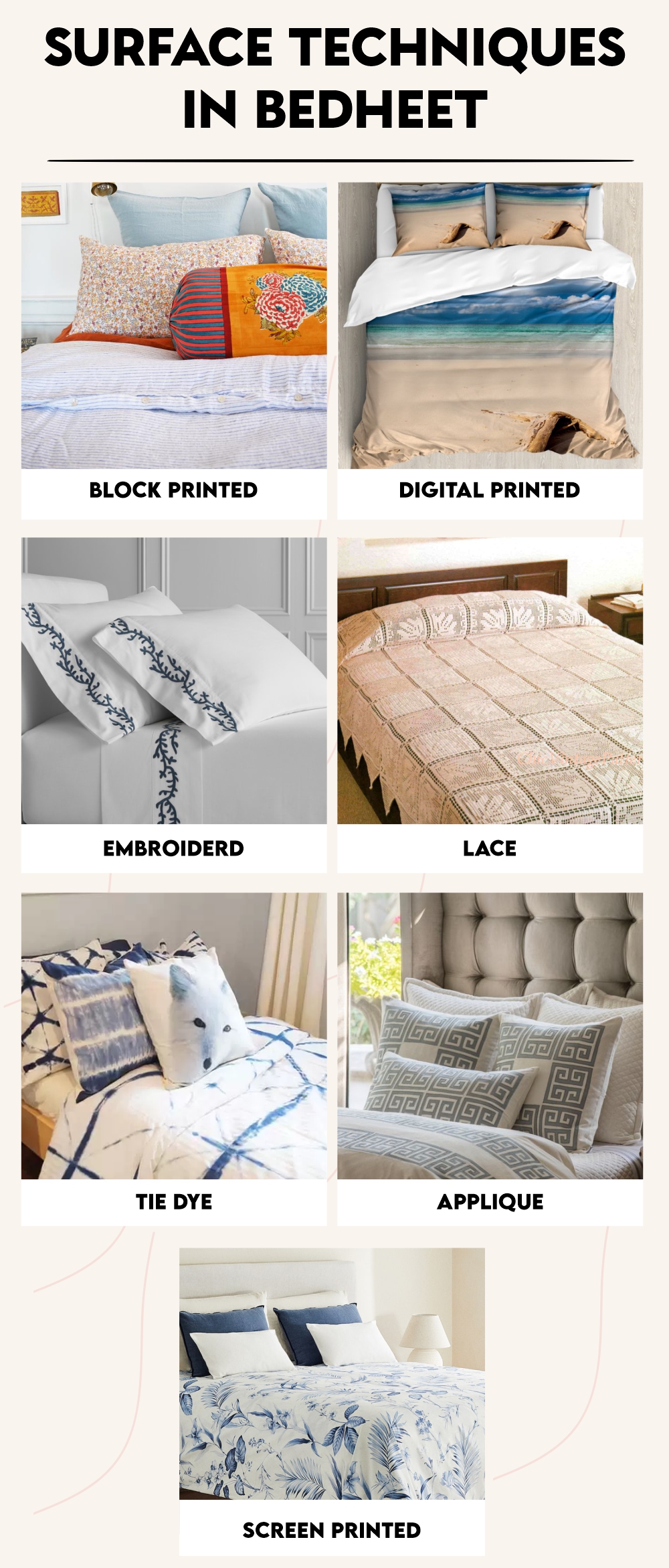

Bed Sheet Printing Process

We spent our first 3-4 months building a brand identity map getting the bare bones website set up getting a logo finalized refining our messaging and setting.

Bed sheet printing process. Ad Buttery Soft Pre-Washed And Designed To Last. Schematic representation of estrusion deposition. I actually have a longer blog post on our site from Week 2 about what we did from October - January.

Schematic representation of. After 24 hours the cloth pieces are taken out and washed thoroughly by hitting them on a big stone. Blue White Printed Bed Sheet With 2 Pillow Covers 2200 1499.

Some FDM 3D printers have two or more print heads to print in multiple colours and use support for overhanging. The acceptable materials used in PBF-type processes are powders of plastics ceramics metals metal alloys or blends of each that fuse upon contact with heat. Describe the process of launching the business.

The 100 pieces are soaked in the mix for 24 hours. A filament a of plastic material is fed through a. A nozzle with liquid material can be drawn over an absorbent surface to wick out material.

-The nomenclature letterpress brings to mind the images of raised letters pressing against a surface on which their shape of ink is transferred. Printed Pattern Bed Cover With 2 Pillow Covers 2200 1499. After a 3D Print is finished the top two sheets easily slide away from.

It can be used to make one or more identical images or to create repeating patterns on papers and textiles. Fresh Breathable Premium Flax Linen. Then the cloth becomes very soft and ready to absorb colour.