Bubbling And Circulating Fluidized Bed

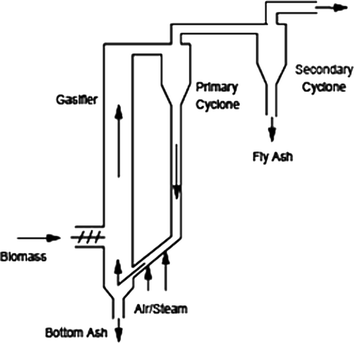

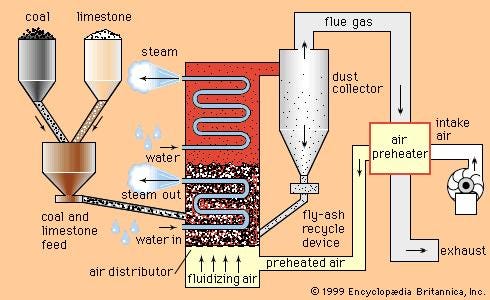

The second type of combustion chamber has a fast bed at the upper part and a bubbling bed at the lower part which is called circulating fluidization.

Bubbling and circulating fluidized bed. The model is used to simulate two industrial units and is validated against steady-state operational data. Bubbling and slugging fluidized beds whereas they overlap substantially with transport reactors. 9 rows The circulating fluidized bed CFB boiler see Figure 8 takes the principle of the.

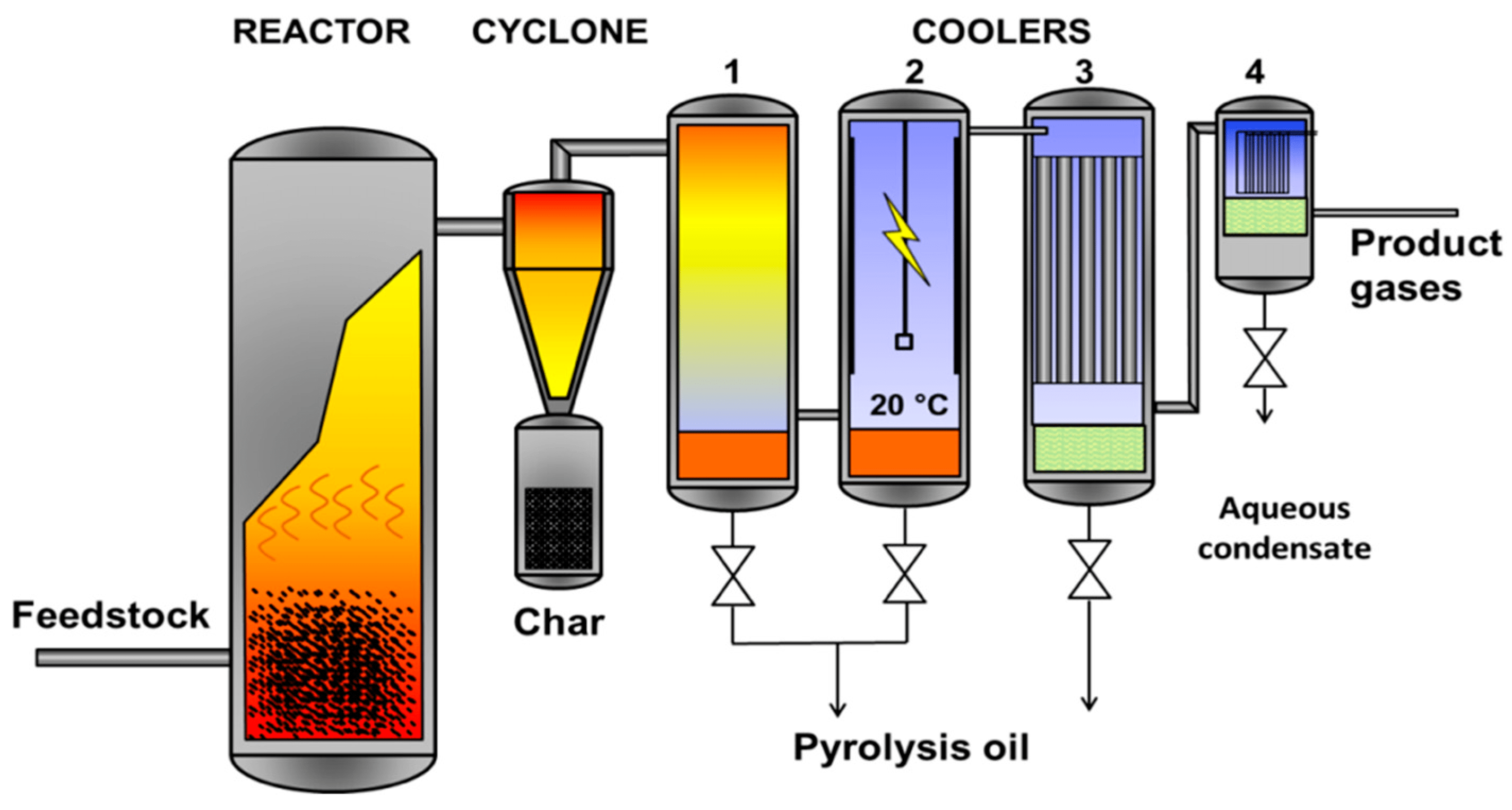

The circulating fluidized bed boiler CFB boiler is the second-generation fluidized bed boiler the updated version of the bubbling fluidized bed boiler BFB boiler. A single biomass gasification unit with either updraft or downdraft design can generate up to 500 kW power while a gasification station with fluidized bed design could have capacity of about 5 MW. In its most basic form fuel particles are suspended in a hot bubbling fluidity bed of ash and other particulate materials sand limestone etc through which jets of air are blown.

This work compares the dynamic behaviour of the flue gas side of large-scale bubbling and circulating fluidized bed BFB and CFB respectively boilers. In bubbling bed particle size used are larger than circulating fluidized bed so power requirement for sizing is less. The first type of combustion is carried out in a bubbling fluidized state which is called a bubbling bed boiler which is also called a fluidized combustion boiler in my country.

An internally circulating fluidized bed ICFB is a type of fluidized bed with a centrally located draft tube or a plate that divides the bed into two or more sections and thus promotes solid circulation within a single vessel. The kinetic information opens the possibility of developing several alternatives using classical bubbling BFB and turbulent TFB fluidized-bed reactors or more performant circulating fluid. That is they move along with the flow of the fluid in the direction when the external plug or pressure valve is activated these clusters of solids can be assumed to possess very high velocity than that of initial solids in this conditions.

With this technique the suspension behavior in an arbitrary cross section can be observed. A more detailed comparison between industrial-size bubbling and circulating fluidized beds is given in Table 8. Use our Online Contact Form or Jansen Combustion and Boiler Technologies Inc.

Fluidized bed combustion FBC is a combustion technology used to burn solid fuels. The results showed that the diameters of bed material in bubbling fluidized bed and circulating fluidized bed were different. In a bubbling fluidized bed.