Bubbling Fluidized Bed Combustion

Circulating fluidized bed boilers are a unique type of boiler that have the ability to combust problematic fuels with a varying composition and characteristic makeup of density moisture content heating value and ash content 231 due to the high heat capacity of the bed material.

Bubbling fluidized bed combustion. One of the main advantages of the fluidized bed technology is its ability to burn various fuels in the same unit. Babcock Wilcox BW has extensive experience with boiler conversions and. Under such sort the main factors leading to fluidization are as follows.

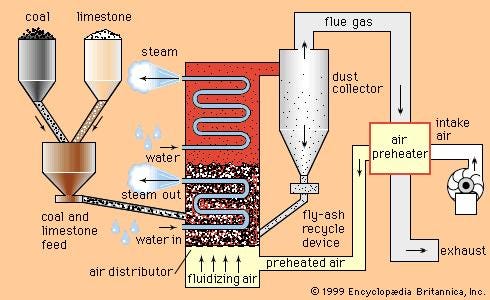

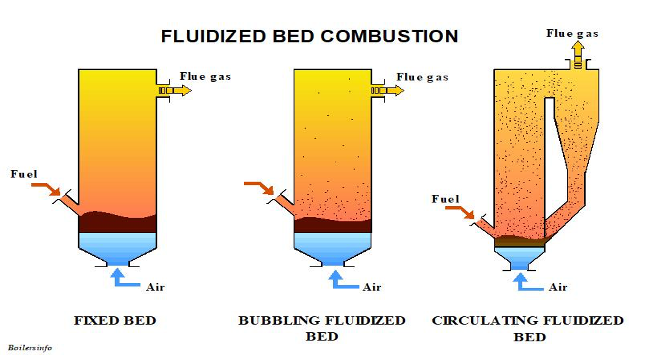

In a CFB unit the velocity is greater and hot particles are circulated through the entire range of the boiler combustion zone. 1 418 833-2110 Fax. Boilers with grates use fixed beds fluidized bed combustion boilers use bubbling fluidized beds or turbulent regime in this case with fly ash recirculation circulating fluidized bed boilers use the fast fluidization regime and pulverized coal combustion boilers work in the pneumatic conveying regime.

In absence of strict pollution norms particularly with NOx bubbling beds continue to be sold only in developing markets for solid fuels such as coal and lignite. Coal of size 0-10mmis spread over bed typically 1-6 mm size for under bed firing and 6-10mm for overbed firing as soon as it reaches bed combustion takes. Bubbling fluidized-bed BFB systems are attractive when wide fuel flexibility is required and for firing high moisture and lower heating value fuels.

1The bed bottom is designated as the inlet from which the mixture of the air and steam is introduced to fluidize the solid material and also as the gasifying agent. Fluidized bed combustion FBC a system in which the fuel eg coal is fed into a solid bed which has been fluidized by an upward movement of air includes technologies such as atmospheric fluidized bed combustion circulating fluidized bed combustion CFBC pressurized fluidized bed combustion pressurized circulating fluidized bed combustion and bubbling fluidized bed combustion. A bubbling fluidized bed combustion system for forest residues.

Fluidized Bed Combustion takes place when the forced draught fan supplies air to the Furnace of the Boiler. 1 Introduction The fluidized bed combustor FBC is a flexible and reliable technology that carries out. Bubbling fluidized bed BFB combustors are of interest for plants with a nominal boiler capacity greater than 10 MW th.

Bubbling FBC is used for Fuels with lower heating values such as Rice Husk. In BFB boilers the velocity of the combustion air is low enough that the fluidized particles remain in the lower furnace. As indicated above fluidized bed combustion originates from the need to burn difficult low grade fuels of varying quality.