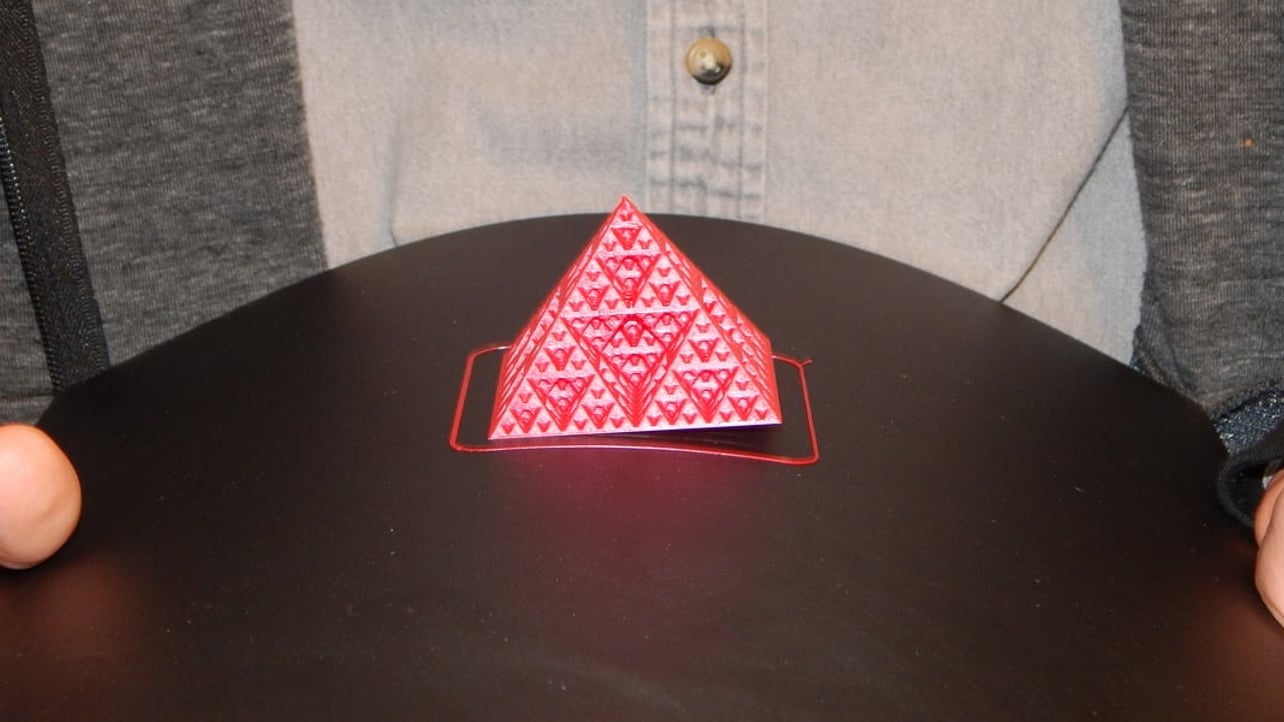

Buildtak Heated Bed

Some people just clean their print bed and adhesion works great.

Buildtak heated bed. Despite its powerful adhesive capabilities Buildtak is still not going to provide enough adhesion to negate the use of a heated print bed. At the current nozzle height the PLA wont stick at all at 190 degrees. Additionally we have had success with getting nylon and t-glase PETT to adhere when used with a thin layer of.

BuildTak is a sheet which sticks down on top of your print bed for better adhesion especially when it comes to PLA and other similar materials. Buildtak problems - nothing sticks to it. T-glass when printed produces clear objects that look very cool.

Ad Check Out Heated Bed on eBay. Also BuildTak wears out over time. BuildTak is a great surface even on unheated beds but prints can stick too well.

This is because of. The heat will help release the BuildTak adhesive and make removal much easier. Otherwise when you remove your print from the bed it may take chunks of the glass with it.

First is to make sure the nozzle is close enough to the build plate. Used it initially on my Anet A6. Heated Bed or Non-Heated Bed.

Uses Folding Fire box. I would do as fred_dot_u initially suggested by increasing the bed temp or using a hair dryer to heat the BuildTak. Part adhesion is essential to successful 3D printing so having a surface that holds heat well and promotes material adhesion across many different types of filaments is very useful.